A supply chain is a complex network encompassing the entire lifecycle of a product or service, from raw material extraction to end-user consumption. It comprises interconnected stages such as procurement, manufacturing, distribution, and retail, involving diverse entities working in unison.

Components/Key Players of a Supply Chain:

- Supply Phase:

- Involves sourcing raw materials or components necessary for production.

- Establishing reliable relationships with suppliers for a smooth supply chain.

- For example, if you’re making a sandwich, the bread, lettuce, tomatoes, butter or margarine, mayo, mustard, etc. could come from multiple suppliers.

- Manufacturing Stage:

- The transformation of raw materials into finished goods occurs during this phase.

- Emphasizes operational efficiency and quality control.

- In the sandwich example the bread, lettuce, tomatoes, and condiments are put together to make the sandwich.

- Distribution Process:

- Includes the transportation and storage of finished products.

- Logistics play a pivotal role in ensuring timely and cost-effective distribution during this phase. For example, Amazon. “2 day free shipping” relies heavily on a variety of logistics.

- Continuing with the sandwich example, the finished sandwiches are transported to the stores or restaurants.

- Retail Sector/Consumers:

-

- Represents the final stage where consumers acquire the end product (whether objects, or a sandwich, product can be in all forms).

- Retailers bridge the gap between producers and consumers.

Briden Solutions: Retailer, www.bridensolutions.ca or inhouse at our Springbank, AB (near Calgary) storefront

Elysian: Manufacturer of our InCaseOf house brand

Success Factors for Working Supply Chains

- Effective communication and collaboration

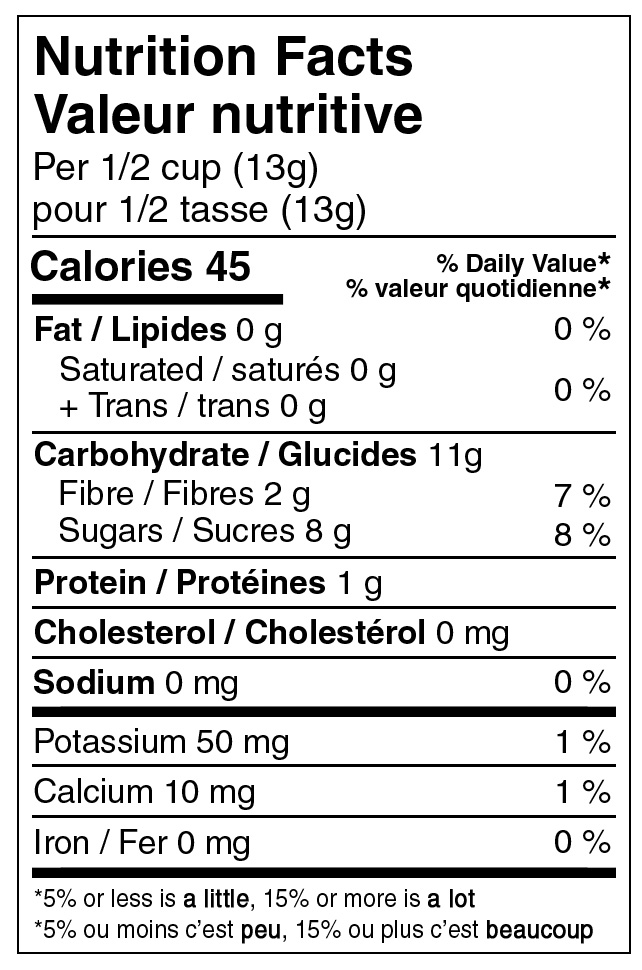

- Following proper rules and regulations for your country of origin. For example: the CFIA (Canadian Food Inspection Agency), and the US FDA (Food and Drug Act)

- Swift response to changes in demand, supply, or external factors

Challenges Within Supply Chains

Disruptions:

- Natural disasters, geopolitical events, or unforeseen crises can disrupt the supply chain.

- The COVID-19 pandemic highlighted vulnerabilities and led to widespread disruptions in the supply chain disruptions due to lockdowns, transportation restrictions, and factory closures.

- Supply & Demand: Inaccurate demand forecasts can lead to overstock or stockouts.

Overreliance on Single Sources:

- Relying on a single supplier or region heightens vulnerability.

- The 2011 earthquake in Japan disrupted global electronics supply chains due to dependencies on Japanese manufacturers.

Ethical and Social Issues:

- Supply chains may encounter challenges related to labor conditions, environmental impact, or ethical sourcing.

- Companies must navigate these issues to preserve brand reputation and consumer trust.

Let’s delve into three specific product supply chain examples

#1 Smartphones:

Supply Phase:

- Materials: Minerals like cobalt, copper, and rare earth metals are sourced from mines globally.

- Components: Manufacturers obtain microchips, displays, and camera modules from specialized suppliers.

Manufacturing Stage:

- Assembly: This is where your “made in China” or “made in Canada” sticker comes into play, during assembly.

- Quality Control: Rigorous quality control processes ensure that each device meets specifications. This would include testing, sampling and inspections, etc. Ideally companies do not want returned product, so often there are many checks and balances in place at the manufacturing stage.

Distribution Process:

- Finished smartphones are transported by air, sea, or land to distribution centers.

- Distribution centers store products before reaching retailers.

Retail Sector:

- Devices are sold through a variety of channels, including carrier stores, electronics retailers, and online platforms.

- The end consumer purchases the smartphone for personal use.

#2 Automobiles:

Supply Phase:

- Raw Materials: Metals, plastics, fabrics, and electronic components are sourced globally (which have their own supply chain process).

- Specialized Components: High-tech components like microcontrollers and sensors are acquired from specialized suppliers.

- Under the hood, interior, & exterior components of a vehicle is vast, forming a substantial amount of supplies from a substantial amount of suppliers.

Manufacturing Stage:

- Final assembly of vehicles occurs in manufacturing plants.

- Inspections and test trials occur before, during and after the manufacturing.

- Components are often delivered as needed to minimize inventory costs.

Distribution Process:

- Finished vehicles are transported to regional distribution centers.

- Cars are distributed to dealerships through a network of transport vehicles (ex: car haulers).

Retail Sector:

- Vehicles are sold through a network of dealerships.

- Consumers visit dealerships to purchase or lease vehicles.

all the tiny particles that do not belong. The mesh lets the clean water through but traps the rest. This method works because those little troublemakers we mentioned earlier are usually larger than the holes in the filter.

all the tiny particles that do not belong. The mesh lets the clean water through but traps the rest. This method works because those little troublemakers we mentioned earlier are usually larger than the holes in the filter. So, the next time you enjoy a glass of clean, safe water, you can appreciate the science behind it. Lets make sure you stay healthy and hydrated, even in emergency situations.

So, the next time you enjoy a glass of clean, safe water, you can appreciate the science behind it. Lets make sure you stay healthy and hydrated, even in emergency situations.